End Forming Machines

High processing precision and short cycle time result in high productivity.

Rotary end formers best-suited for a wide range of operations from common processing performed with a punch or die held against a workpiece to the formation of inner or outer grooves through the rotation of a tool. A lineup of spinning machines that perform the forming operation by rotating workpieces and many other similar machines. A variety of tube diameters, small and large, can be handled.

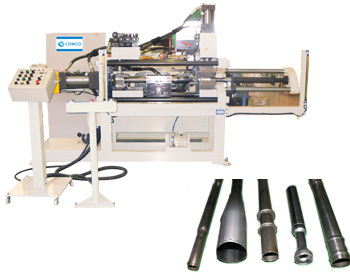

Punch and die end formers (for small diameter workpieces) Model: KE-20

Tube outside diameter: φ20 Í t1.6(STKM11A)

Punch thrust About 4.5 tons

Processing speed

About 3 seconds/1 punching operation

About 5 seconds/2 punching operations

About 7 seconds/3 punching operations

Can handle various materials such as iron, stainless steel, and copper.

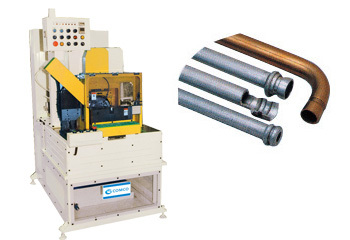

Punch and die end formers (for large diameter workpieces) Model: KE-50

Tube outside diameter: φ50 × t2.0 (STKM11A)

Punch thrust About 15 tons

Processing speed

About 5 seconds/1 punching operation

About 8 seconds/2 punching operations

About 12 seconds/3 punching operations

Can also handle operations to enlarge or reduce tubes.

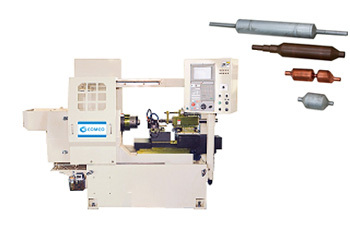

Rotary end former. Capable of grooving a tube end face.

Spinning end former. Capable of swaging.

+420 725 178 028

+420 725 178 028