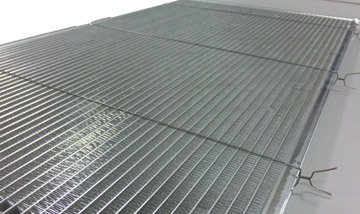

Wire Tying Machines

Streamlines of the furnace brazing process : WOS Wire Tying machines

COMCO WOS Wire Tying machines eliminate the use of brazing jigs for brazed heat exchangers. Process cost reductions include:

- Braze jig cost elimination

- Furnace throughput increase

- Furnace energy reduction

- Improved braze quality

Full Automatic: WOS-A series

- Fully automated wire winding

- Single or multiple simultaneous wire application

- Numerical wire tension and core compression control

Semi Automatic: WOS-S series

- Semi automatic wire tying

- Numerical wire tension and core compression control

Optional Features

- Servomotor controlled core compression

- Load Cell core compression force measurement and display

- Automated wire position-to-position indexing

- Cycle time control of process cycles

- Custom features by request

Wire tying position is programable

Multiple wire tying head for better output

Benefits of Wire Tying for Brazing

- Wire elastic properties reduce compression buckling of fins during brazing

- Elimination of model specific brazing jigs

- Elimination of brazing jigs storage areas frees plant floor space

- Elimination of brazing jigs maintenance labor and costs

- Reduced furnace energy cost

- Increased furnace throughput

- Increased furnace conveyor belt and muffle life

For more detail, or a consultation, contact a COMCO worldwide regional location or office.

Wire bobbin brake system for stable wire tension control

+420 725 178 028

+420 725 178 028